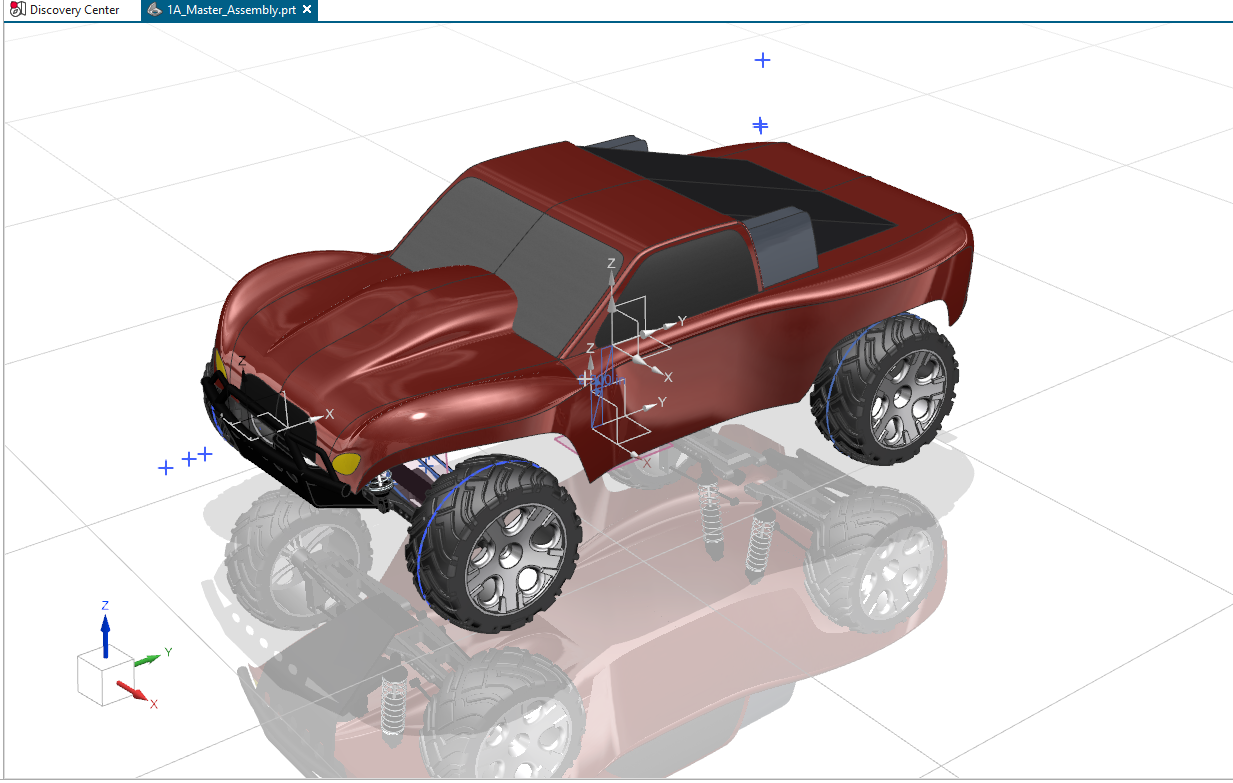

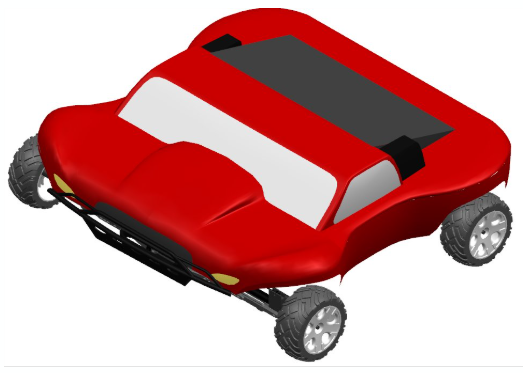

Parametric Assembly and Aerodynamic Analysis of an RC Car

RC car vehicle optimization based on aerodynamics and topology

Project Overview

Role

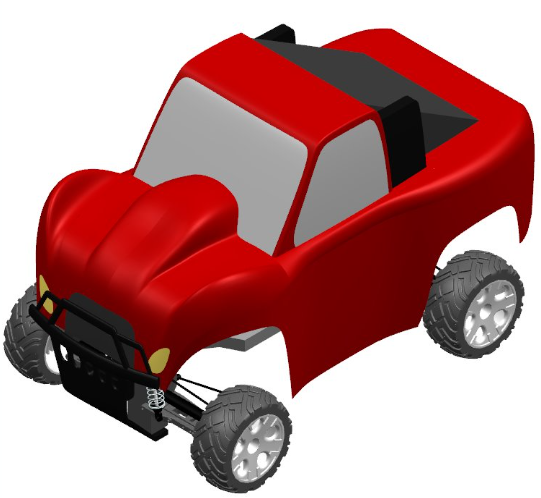

I was responsible for all of the modeling work, including the creation of the shell, skeleton model, and the parametric CAD parts. This involved reverse-engineering the RC car and building a digital model that could be used for various engineering analyses.

Project Duration

Spring 2025 Semester

Key Skills

CAD · Parametric Modeling · CFD · FEA · Topology Optimization · Team Organization

Tools/Software

Siemens NX · Siemens STAR-CCM+ · SolidWorks · Altair Inspire · GrabCad · Microsoft Excel

Project Description

The Challenge

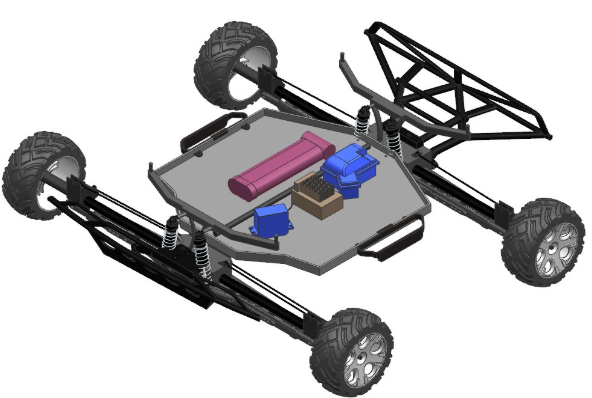

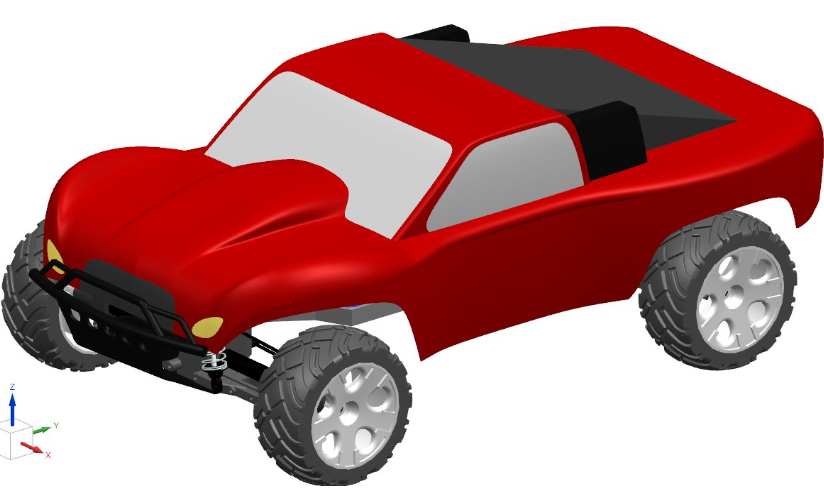

The objective of this project was to reverse-engineer and recreate a Traxxas RC car in a full parametric CAD assembly. The goal was to build a digital model that could be easily modified and then used to perform advanced engineering analyses, including Computational Fluid Dynamics (CFD), Finite Element Analysis (FEA), and Topology Optimization, with the aim of improving overall vehicle performance.

The Approach

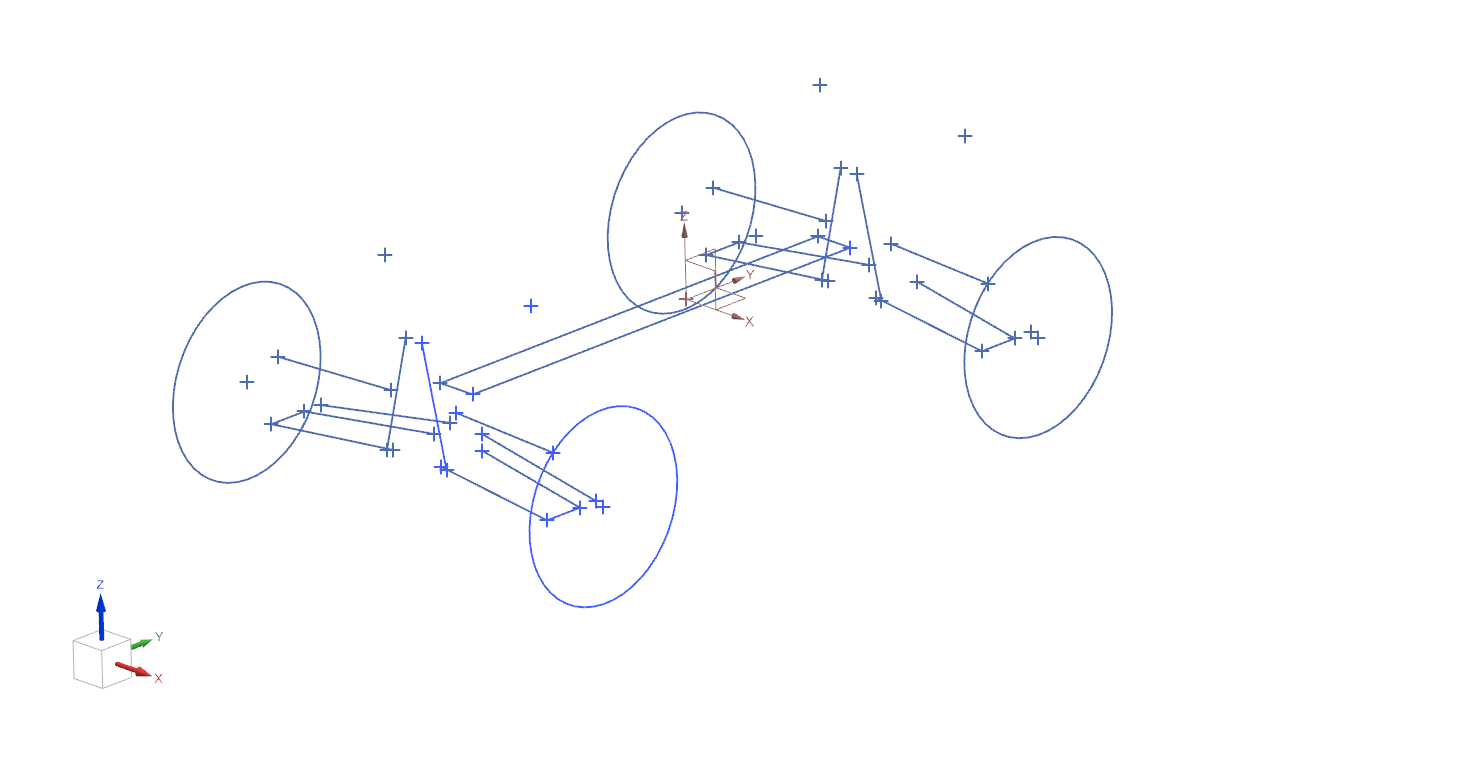

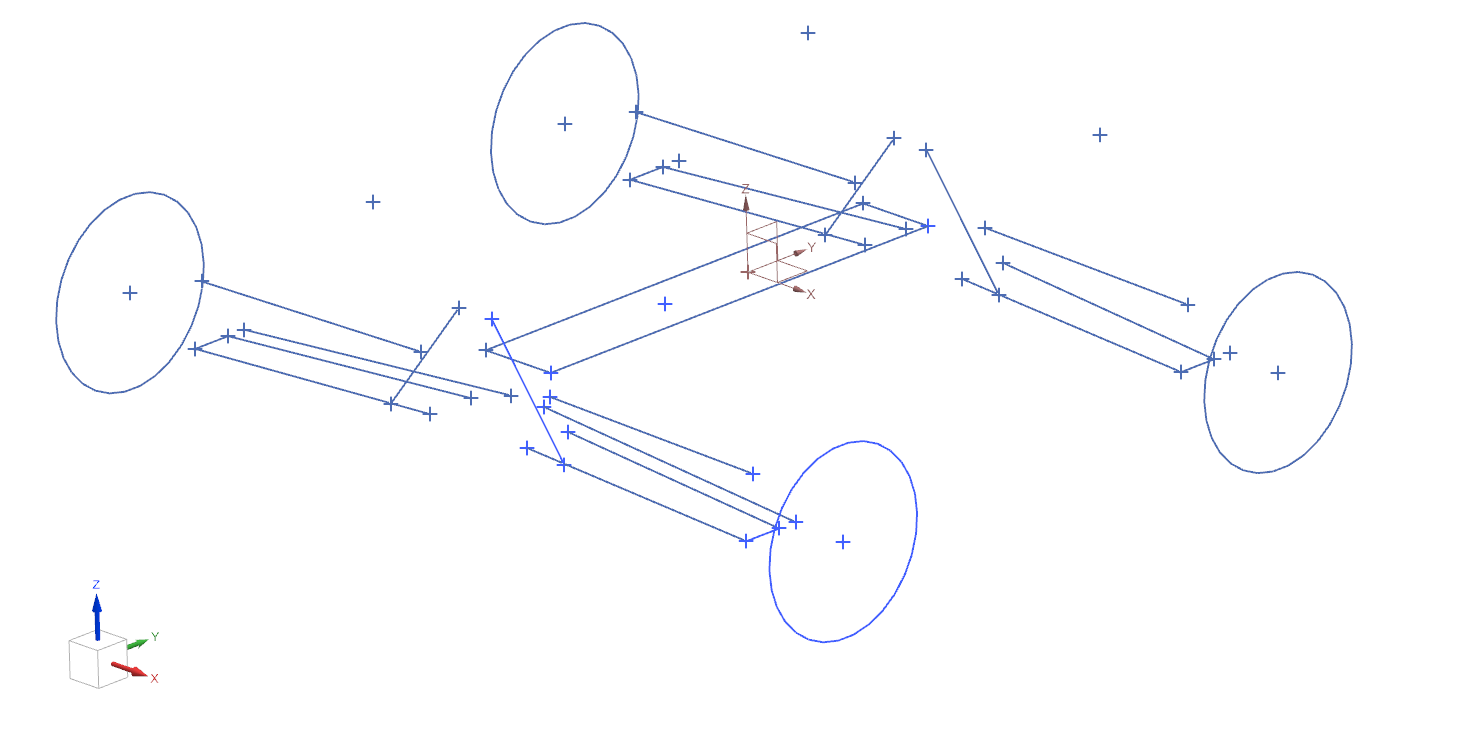

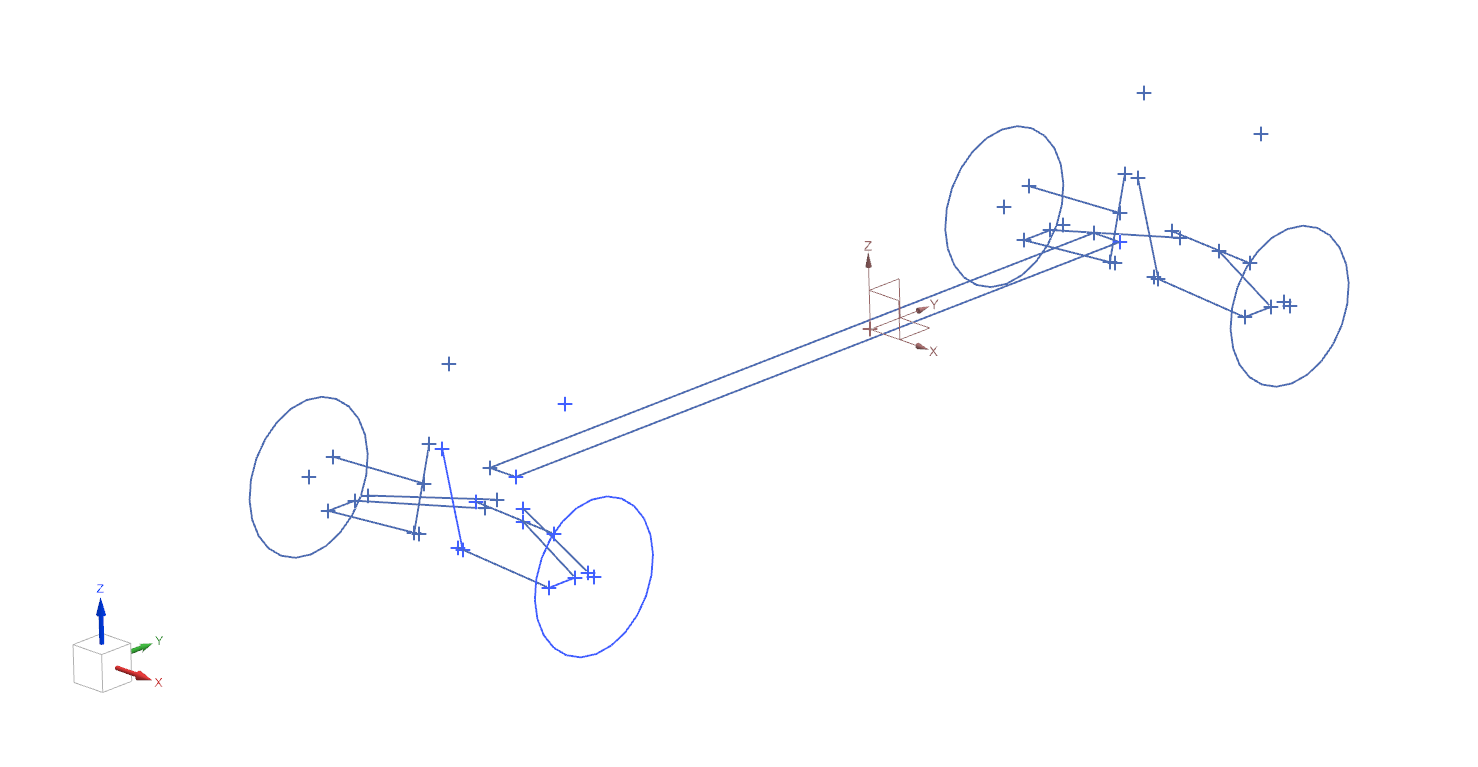

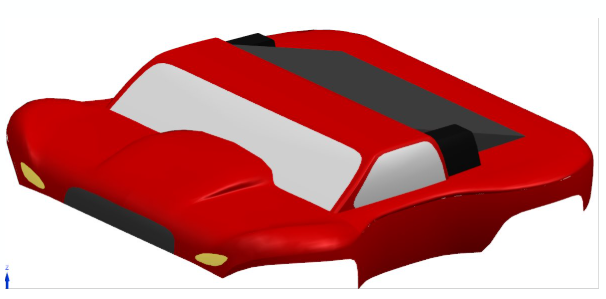

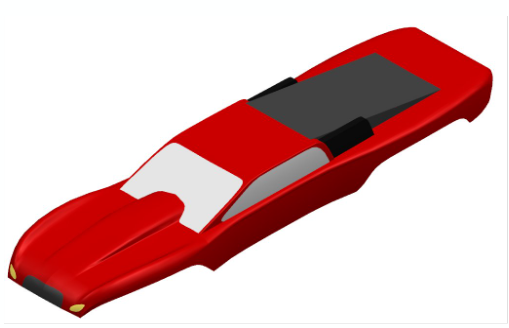

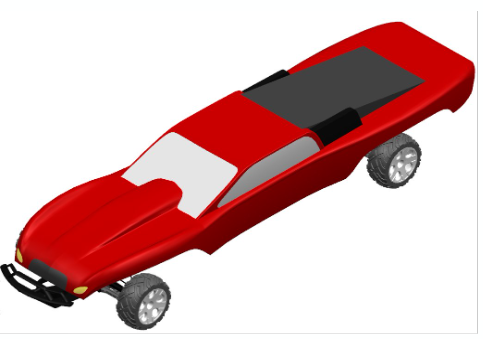

The project followed a collaborative approach, beginning with a detailed file organization and a parametric assembly skeleton to ensure all parts worked together smoothly. We were responsible for designing the car’s shell, modeling complex, organic shapes using surface modeling techniques, and creating the final assembly that incorporated all components. We used parametric modeling to ensure parts adapted correctly to design changes.

To improve performance, we conducted CFD simulations on an initial shell design and then used those results to create a more aerodynamic version, which significantly reduced drag. We also performed FEA on key components like the chassis and bumpers to test their structural integrity under load. In addition, we used topology optimization to reduce weight while maintaining strength. This experience refined our skills in precision modeling, part organization, and documentation, highlighting the importance of careful planning in complex, collaborative projects.

The Outcome

The project was a complete success. Our final CAD assembly accurately recreated the RC car and its components, with a total mass of 6.224 lbs, which was very close to the actual mass of 6.375 lbs. The parametric assembly allowed for easy morphing of the car’s dimensions. The CFD analysis on my redesigned shell showed a significant 47% decrease in drag force, a major improvement. Furthermore, topology optimization on the chassis resulted in a 24% weight reduction. This project provided a comprehensive, hands-on experience in the entire engineering design process, from CAD modeling to advanced simulation and optimization.

Visual Showcase

Official Report

If you would like to review the full details of this project, you can download the complete reports here: