Residual Stress After Interlayer Shot Peening

An investigation into hybrid additive manufacturing for 316L stainless steel

Project Overview

Role

As a member of a research team, I contributed to this project by fabricating and testing specimens, collecting data, and co-authoring the final paper. I focused on investigating the effects of interlayer shot peening on the residual stress of 316L stainless steel parts.

Project Duration

Spring 2025 Semester

Key Skills

Additive Manufacturing · X-Ray Diffraction · Electrochemical Etching · Residual Stress Analysis · Technical Report Writing

Tools/Software

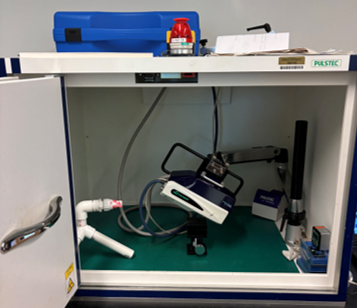

Matsuura Lumex Avance-25 · Sentenso ProcessMaster · Pulstec micro-X360 · MATLAB · Microsoft Excel

Project Description

The Challenge

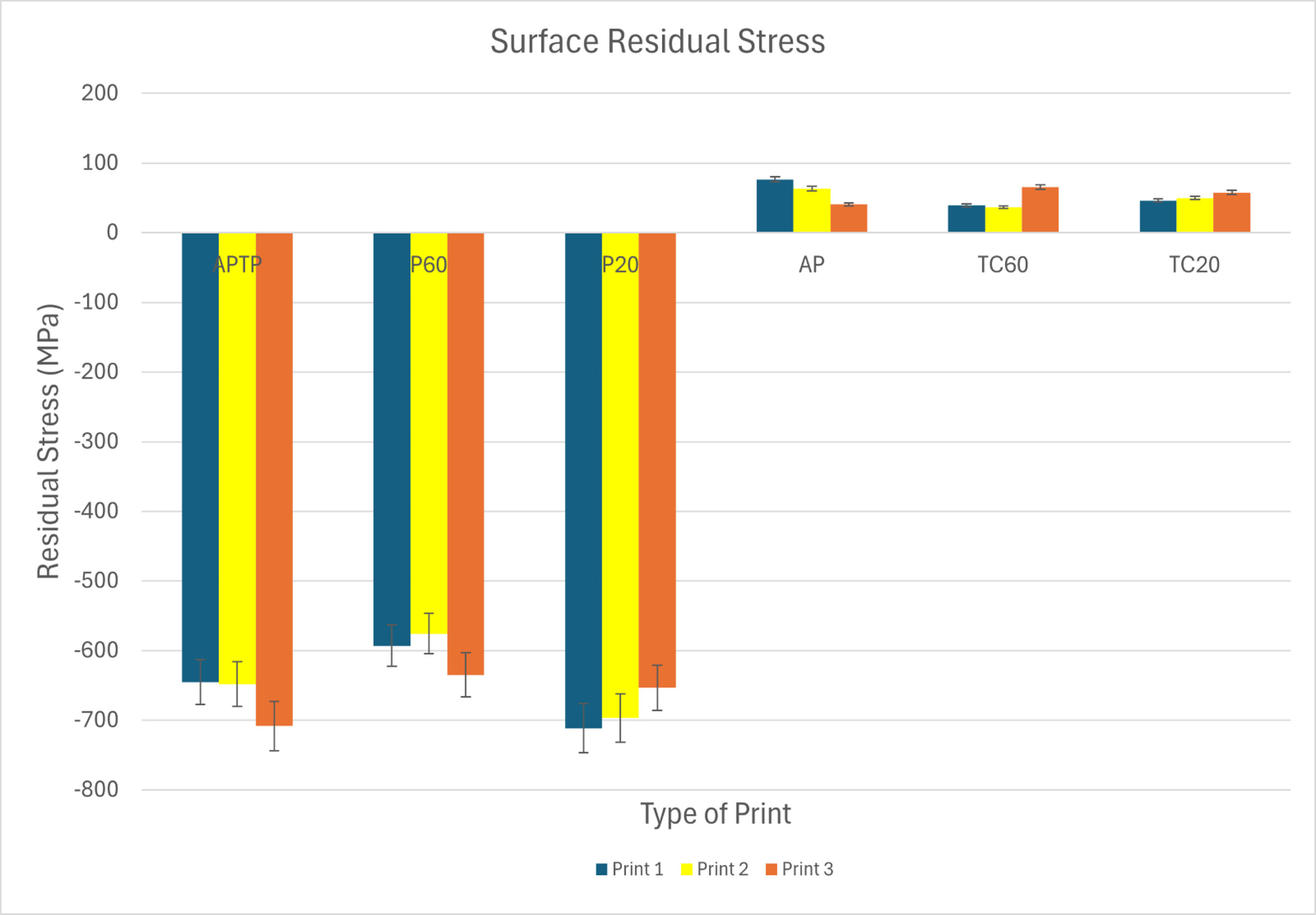

The primary challenge in laser powder bed fusion (LPBF) additive manufacturing is managing residual stress. The rapid heating and cooling cycles of the process can cause thermally induced tensile stresses, leading to part distortion, cracking, and reduced fatigue performance. Our research objective was to test the hypothesis that increasing the frequency of interlayer shot peening could induce multiple compressive stress regions, thereby mitigating these tensile stresses and improving the part’s mechanical integrity.

The Approach

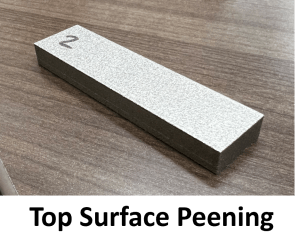

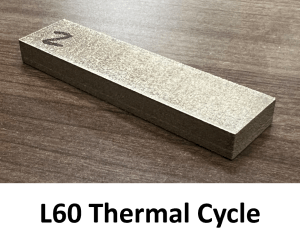

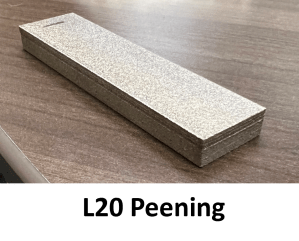

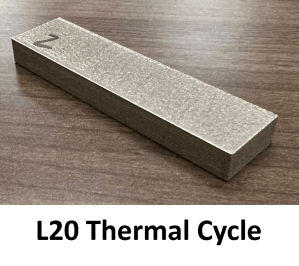

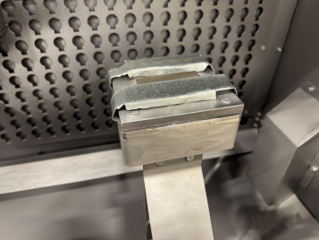

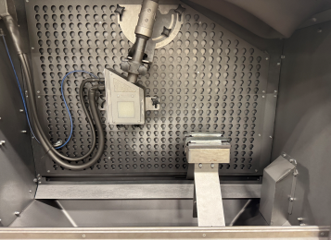

Our team fabricated specimens of 316L stainless steel using an LPBF system. We created multiple test configurations, including a control group with no treatment, a group with post-process peening, and two groups with shot peening applied at different intervals: every 20 layers (P20) and every 60 layers (P60).

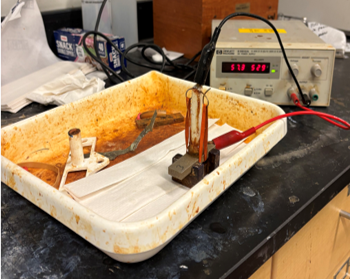

To analyze the specimens, we used X-ray diffraction (XRD), following ASTM E2860-20 guidelines, to measure the residual stress. To get subsurface measurements, we used a process called electrochemical etching to progressively remove layers of material. This allowed us to create a depth profile of the residual stress, giving us a comprehensive view of how the different peening frequencies affected the internal stress distribution.

The Outcome

Our findings confirmed our hypothesis. The results showed that all shot-peened samples exhibited high-magnitude compressive residual stresses, while the untreated samples retained tensile stress. More importantly, the samples peened at a higher frequency (P20) induced a deeper and more intense compressive stress profile, effectively delaying the onset of tensile stress compared to the P60 samples. This deeper compressive zone could significantly enhance the structural integrity of additively manufactured components in fatigue-sensitive applications. This study highlights the value of interlayer shot peening as an in-process strategy for residual stress management.

Visual Showcase

Official Report

If you would like to review the full details of this project, you can download the complete reports here: