Spine Align Posture Correction Device

Design and prototyping of a mechanical solution for improving posture and backpack comfort

Project Overview

Role

As a member of the team, I helped with the research, concept generation, and CAD modeling. I was specifically responsible for creating engineering drawings and developing a financial analysis to validate the project’s viability.

Project Duration

Fall 2023 Semester

Key Skills

Product Design · CAD (Fusion 360) · Prototyping · Stress Analysis · Financial Analysis · Market Research · Engineering Report Writing

Tools/Software

Fusion 360 · Patent Files · 3D Printer · MATLAB · Microsoft Excel

Project Description

The Challenge

The project aimed to address the issue of back pain in college students caused by carrying heavy backpacks and poor posture. Our research, including a student survey, confirmed that carrying a backpack was the leading cause of back and shoulder pain. The goal was to design a single, innovative product that could both correct posture and better distribute the weight of a backpack, a solution that didn’t exist in the current market.

The Approach

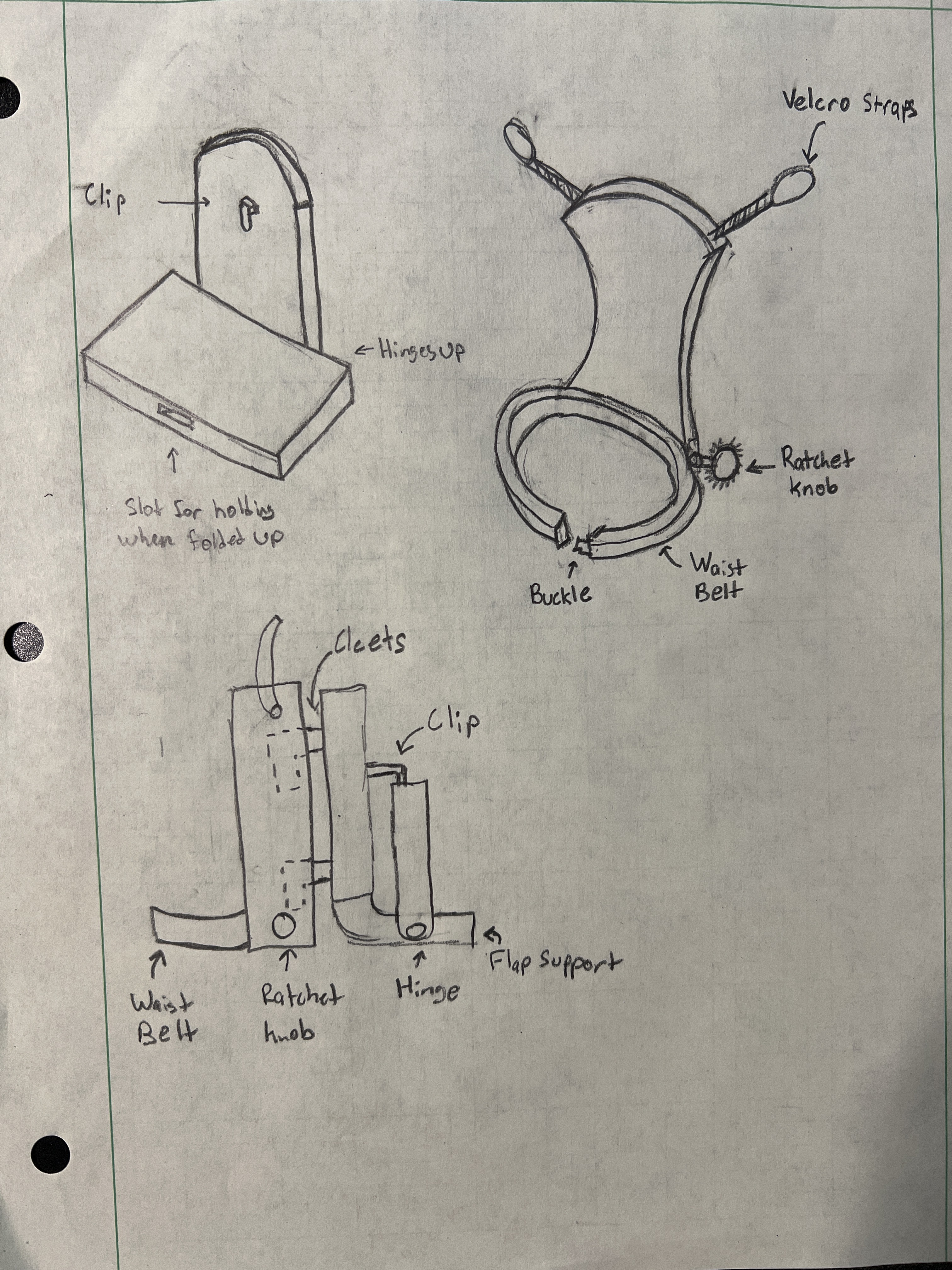

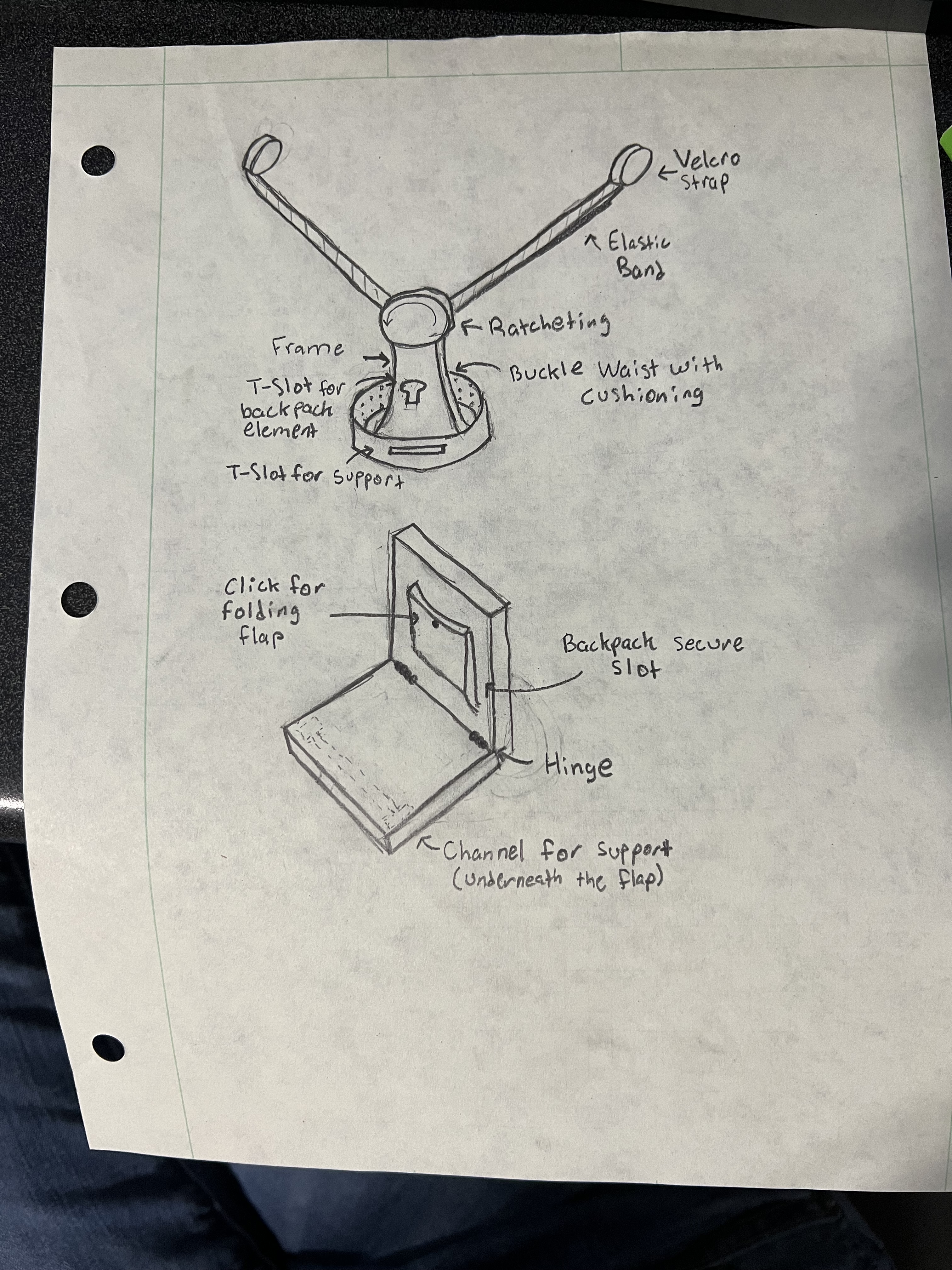

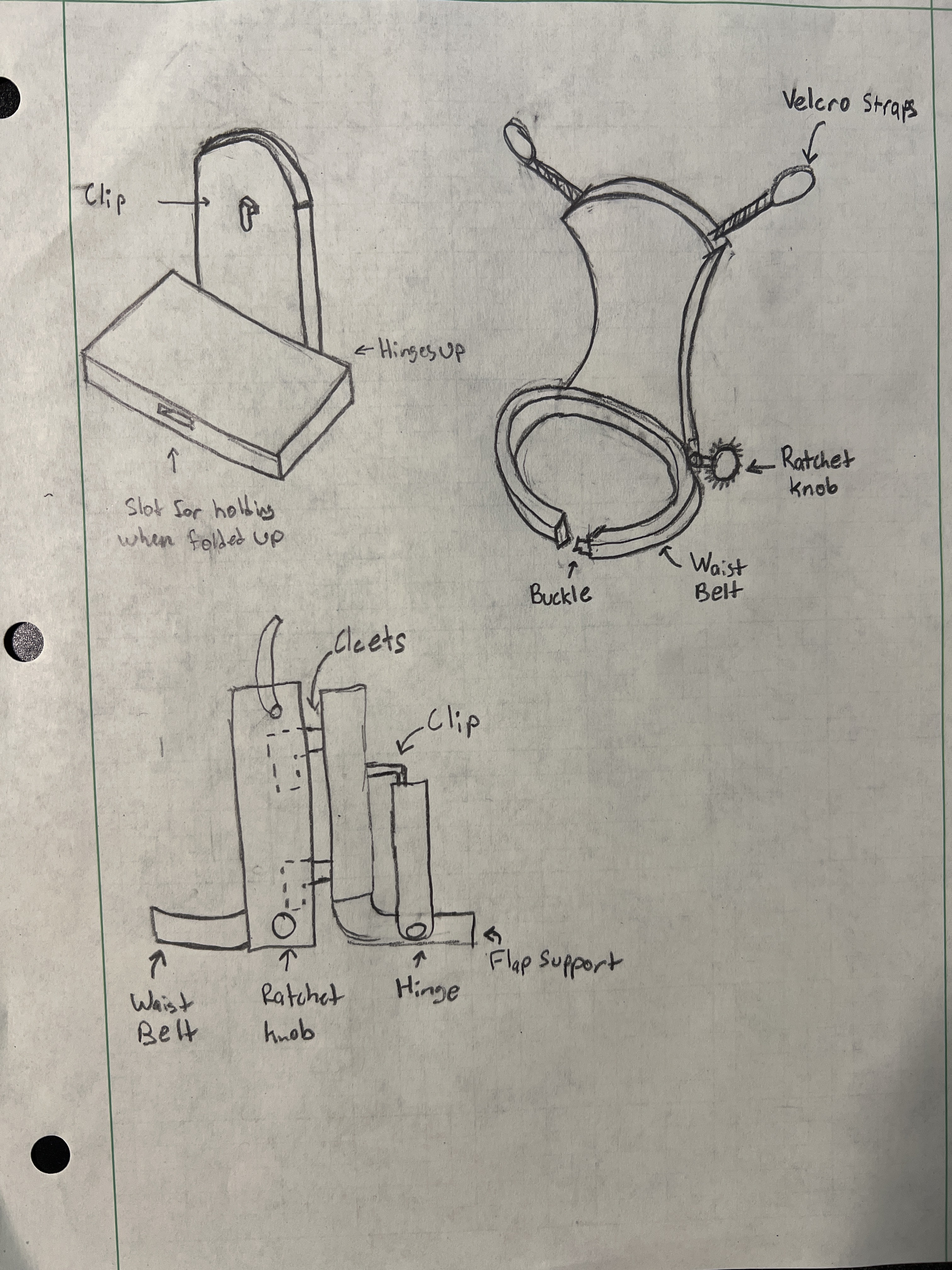

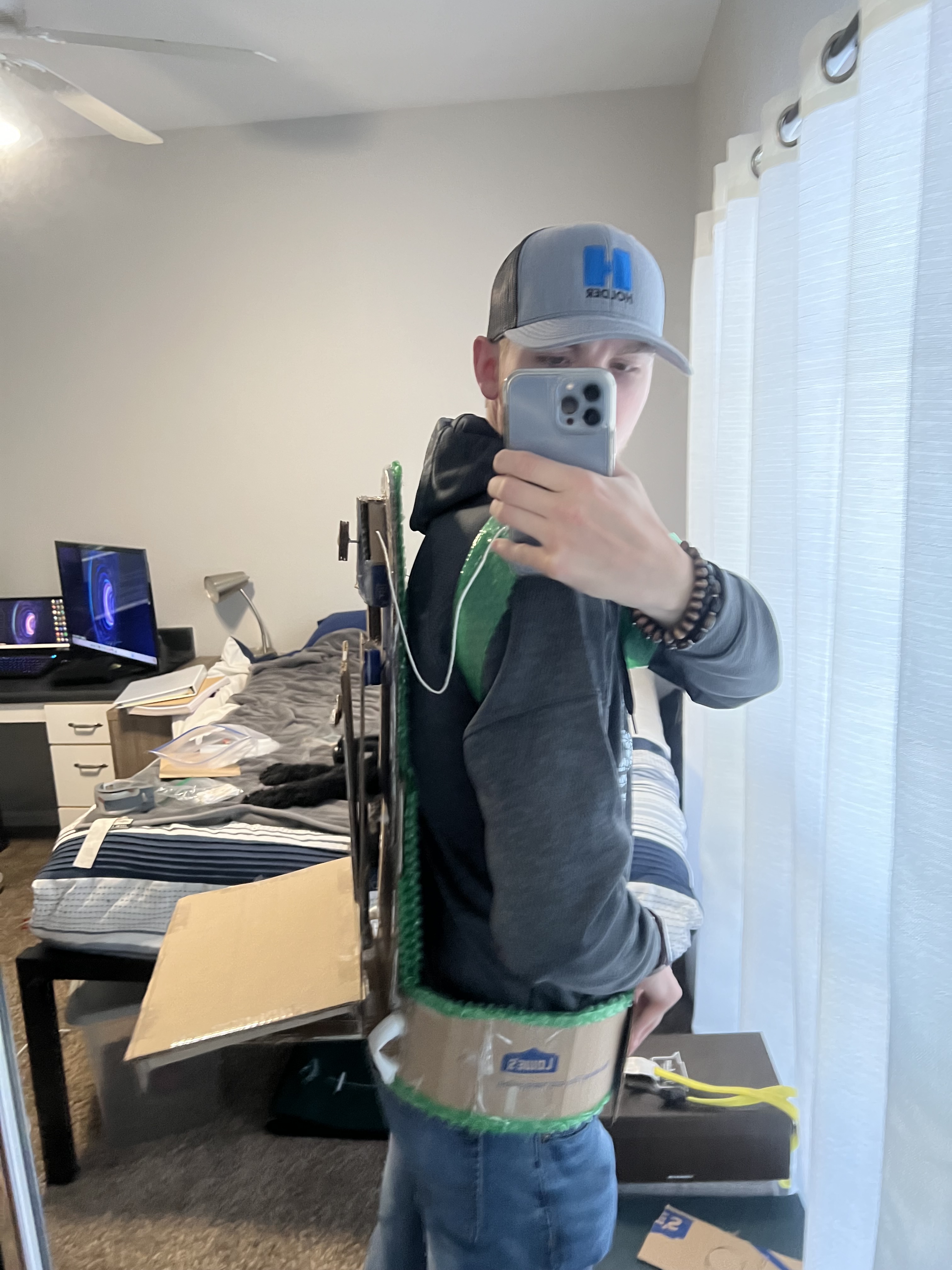

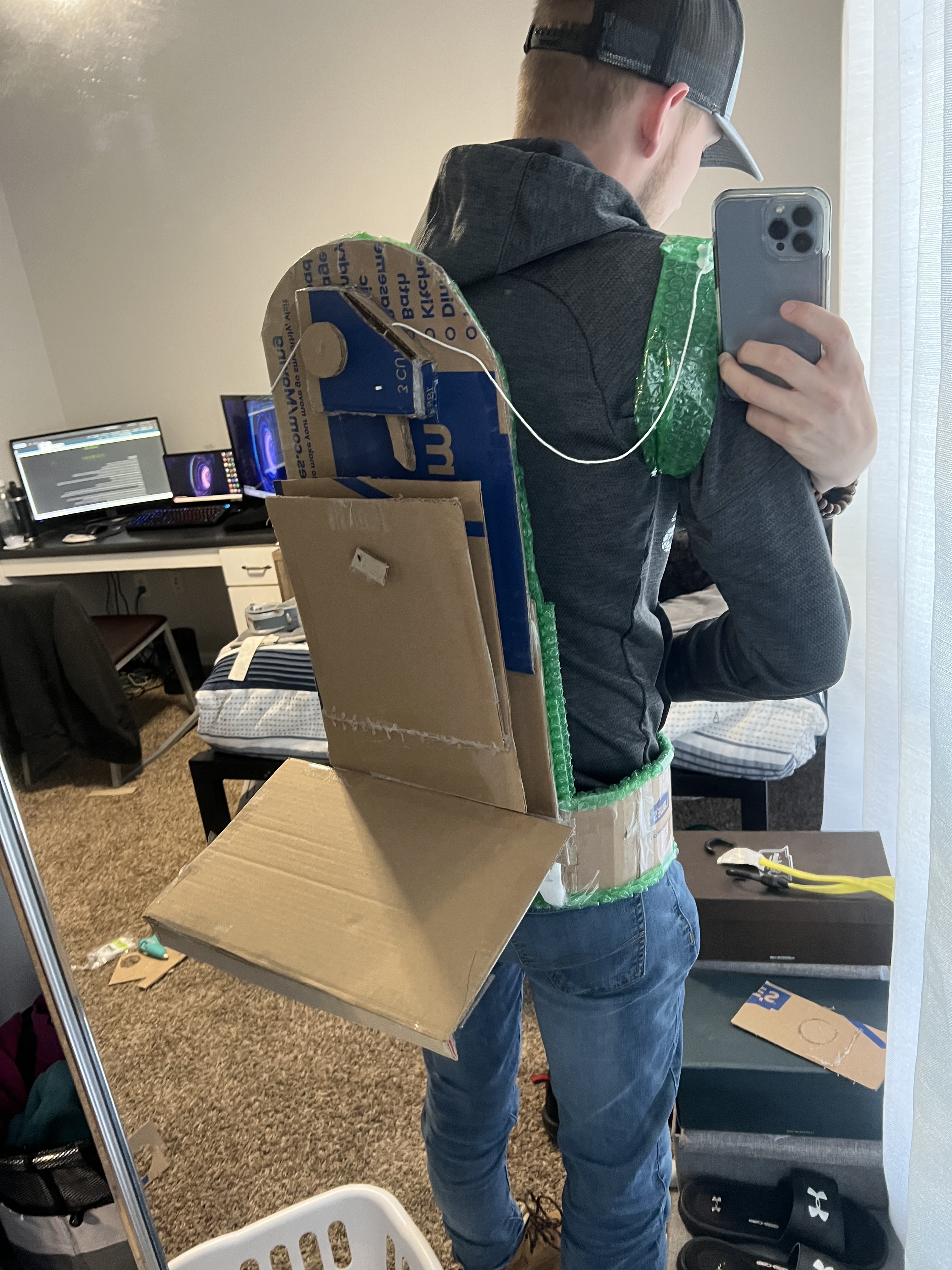

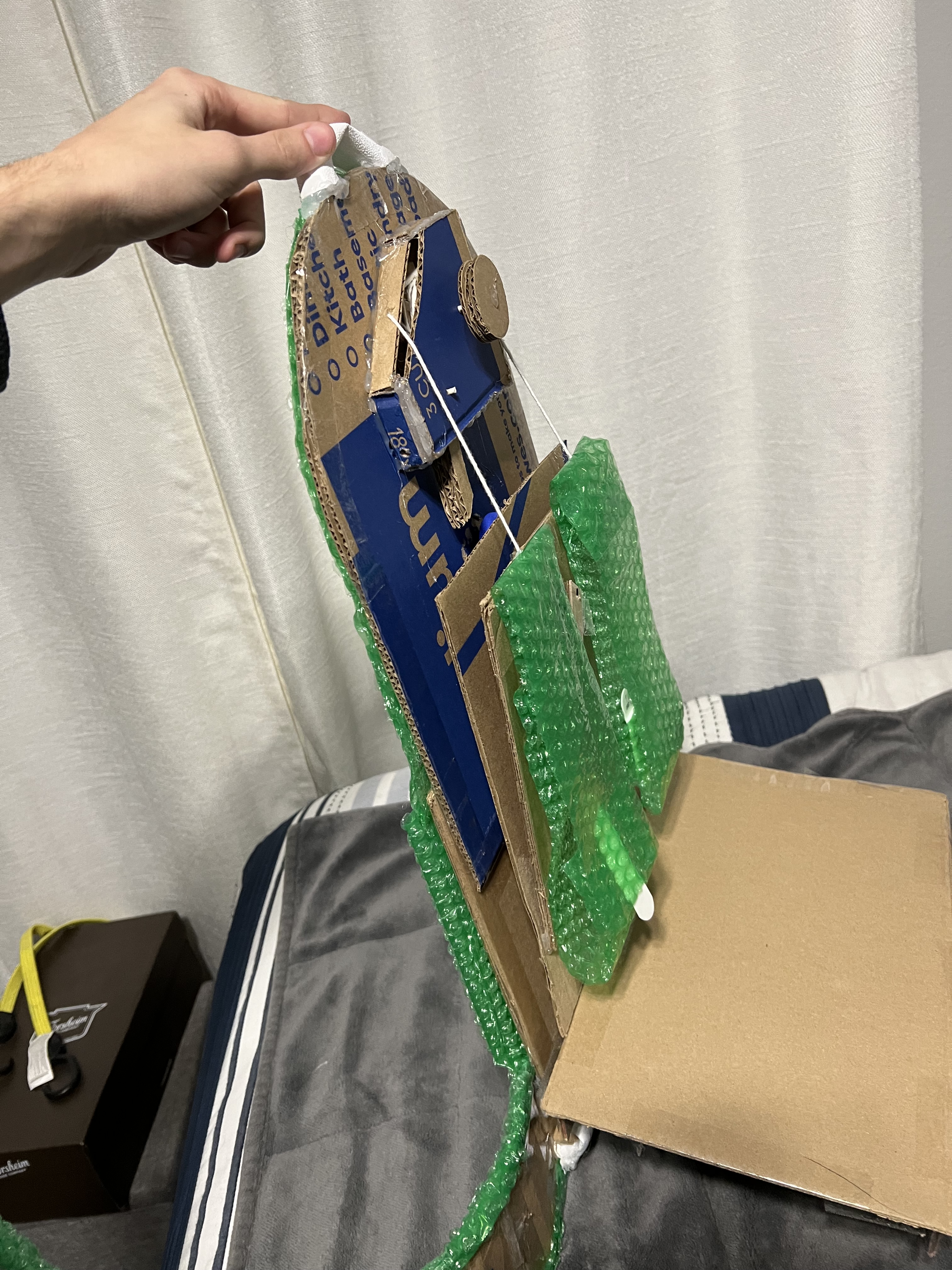

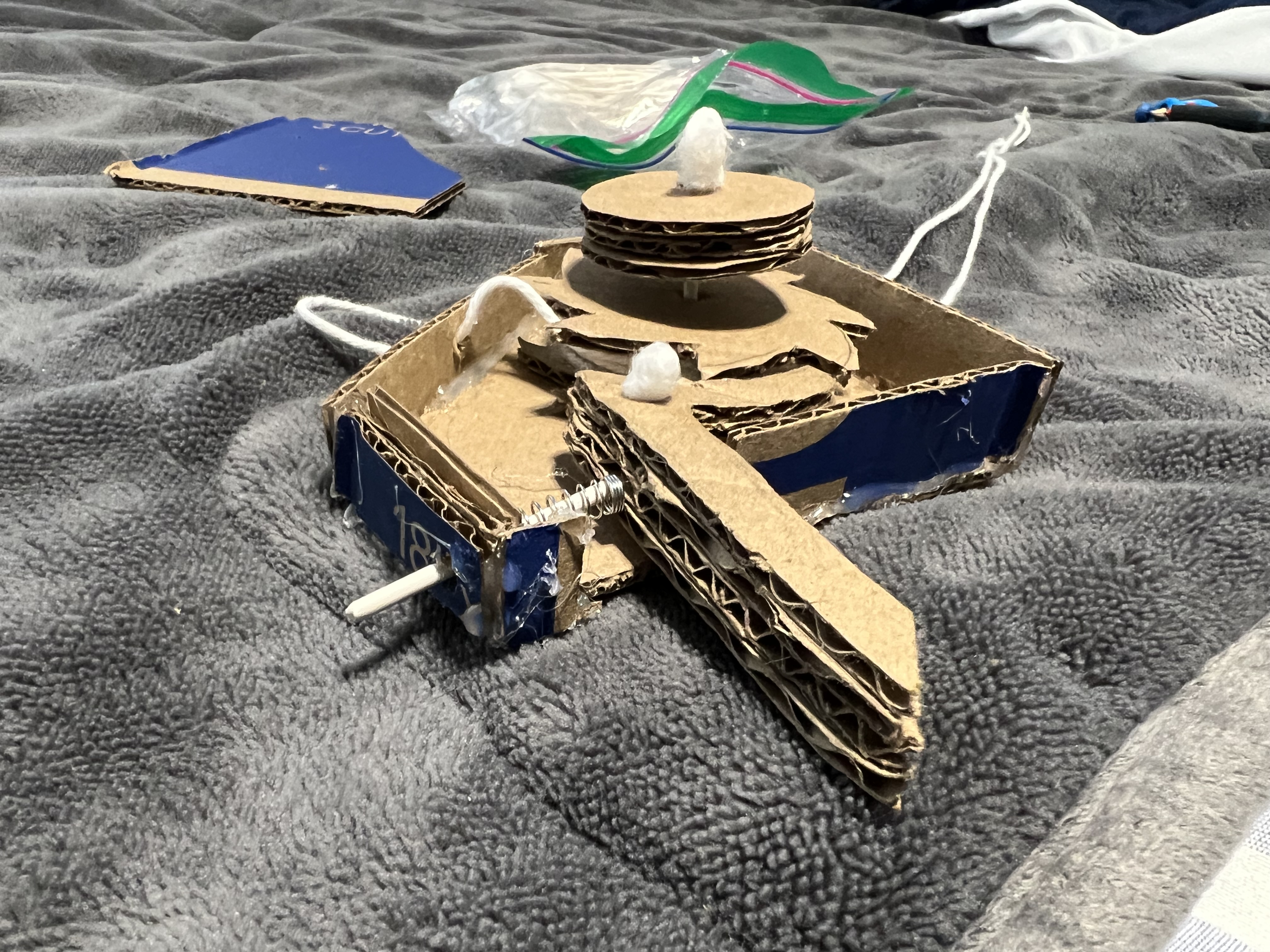

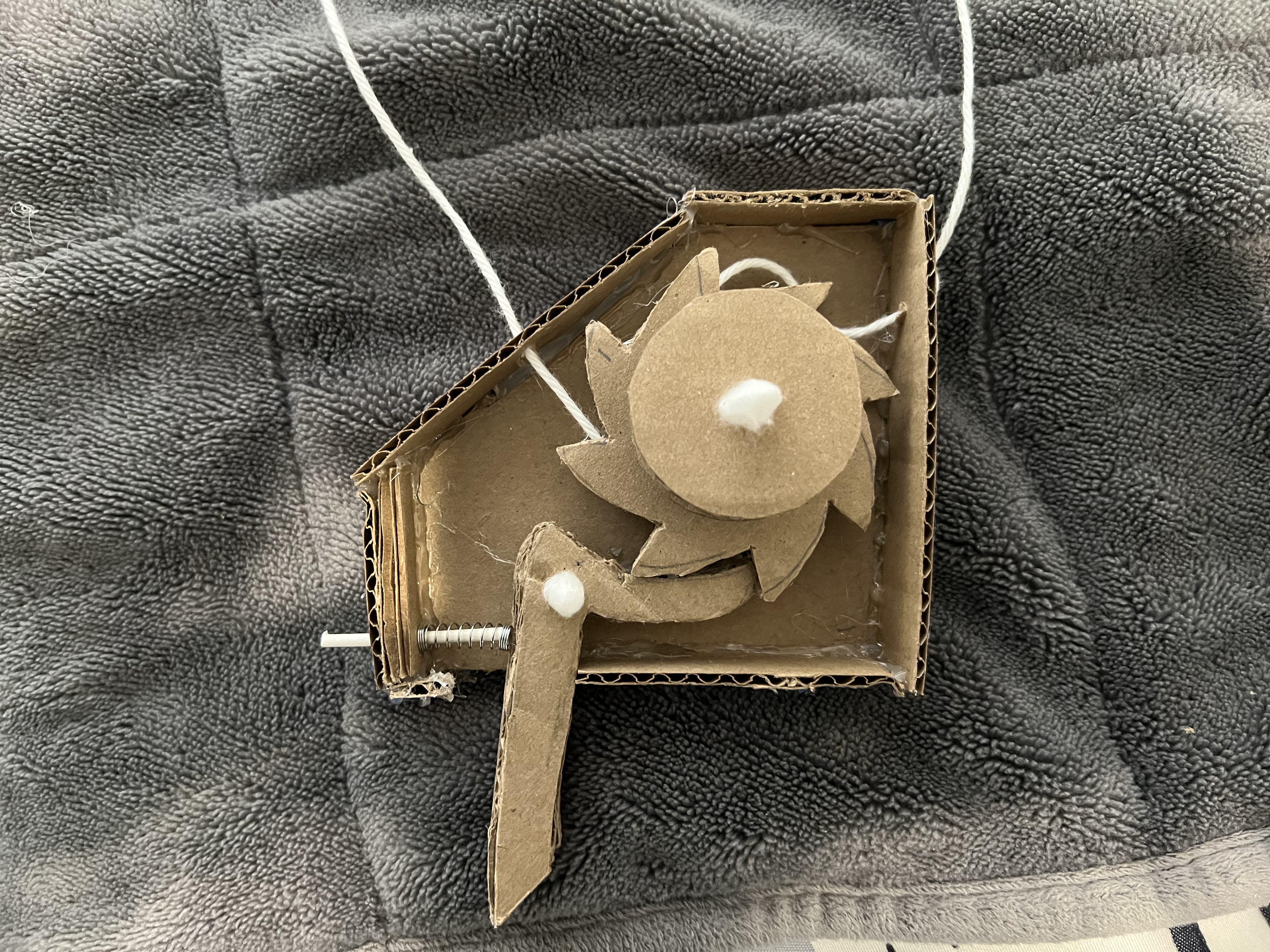

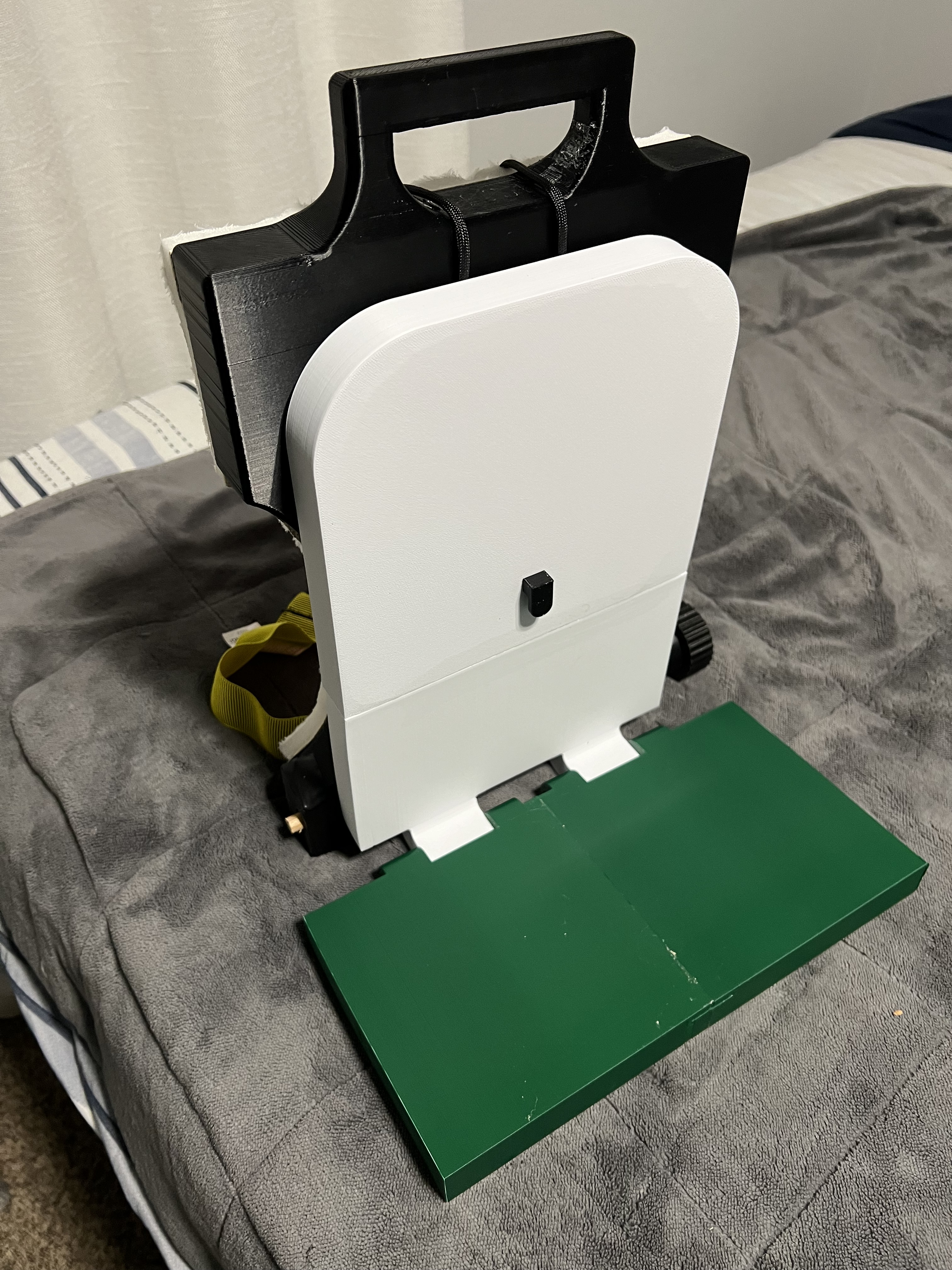

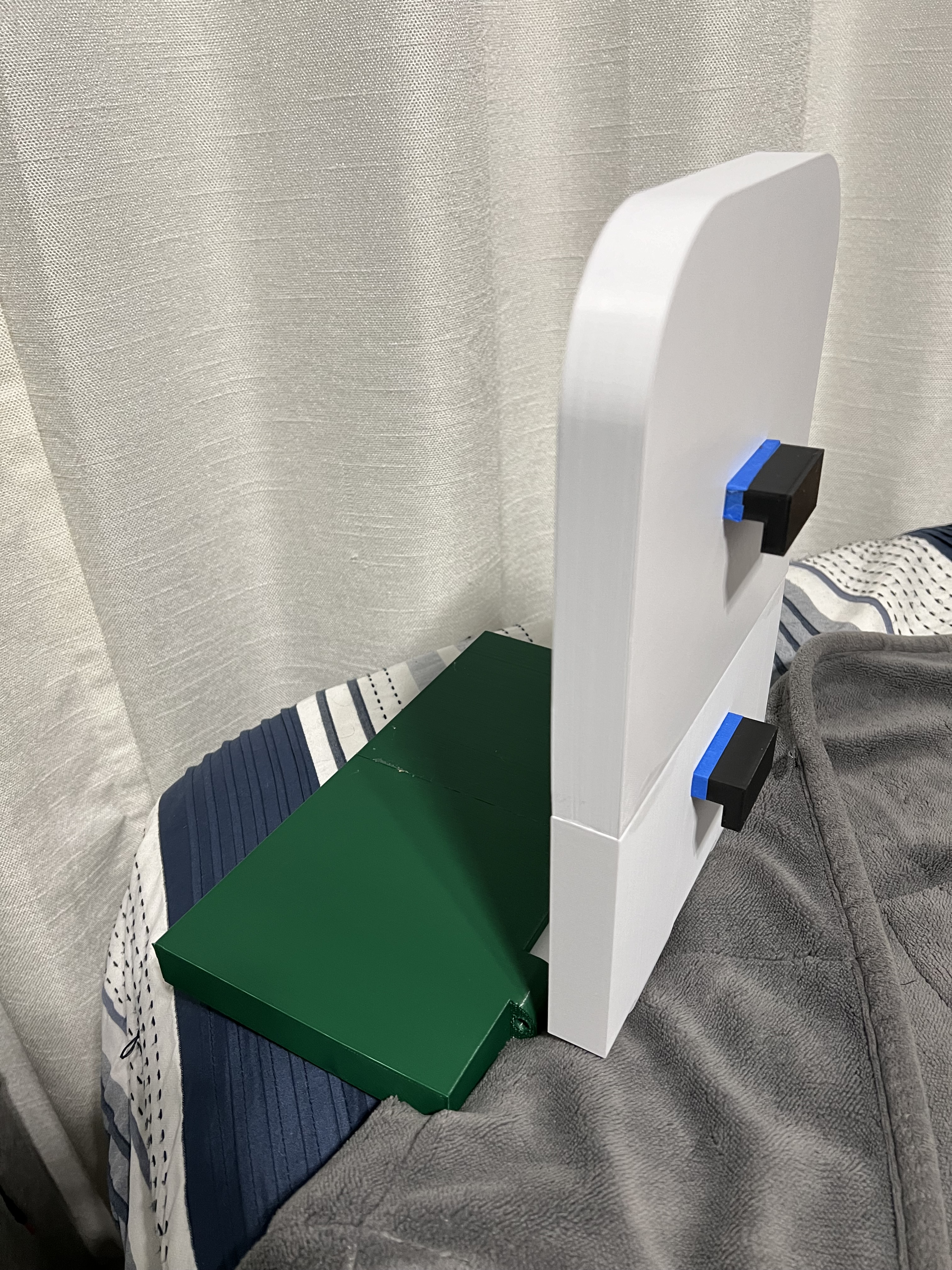

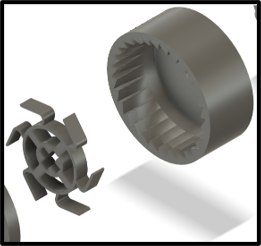

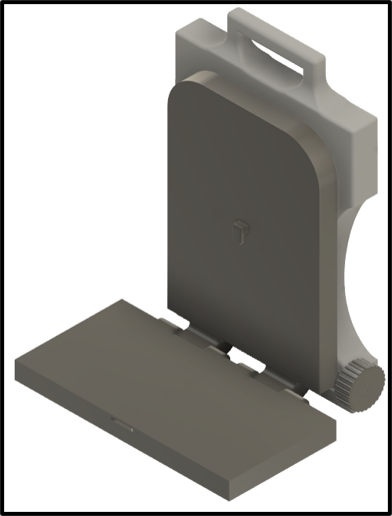

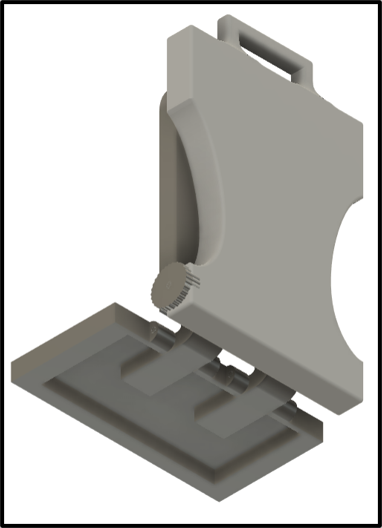

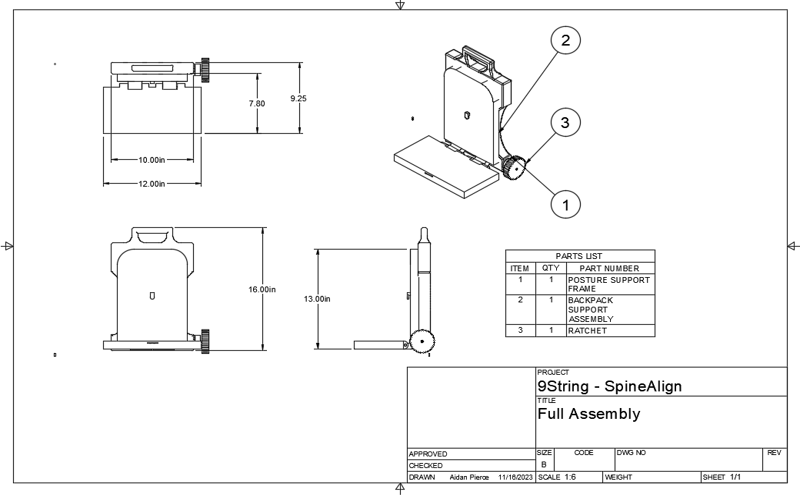

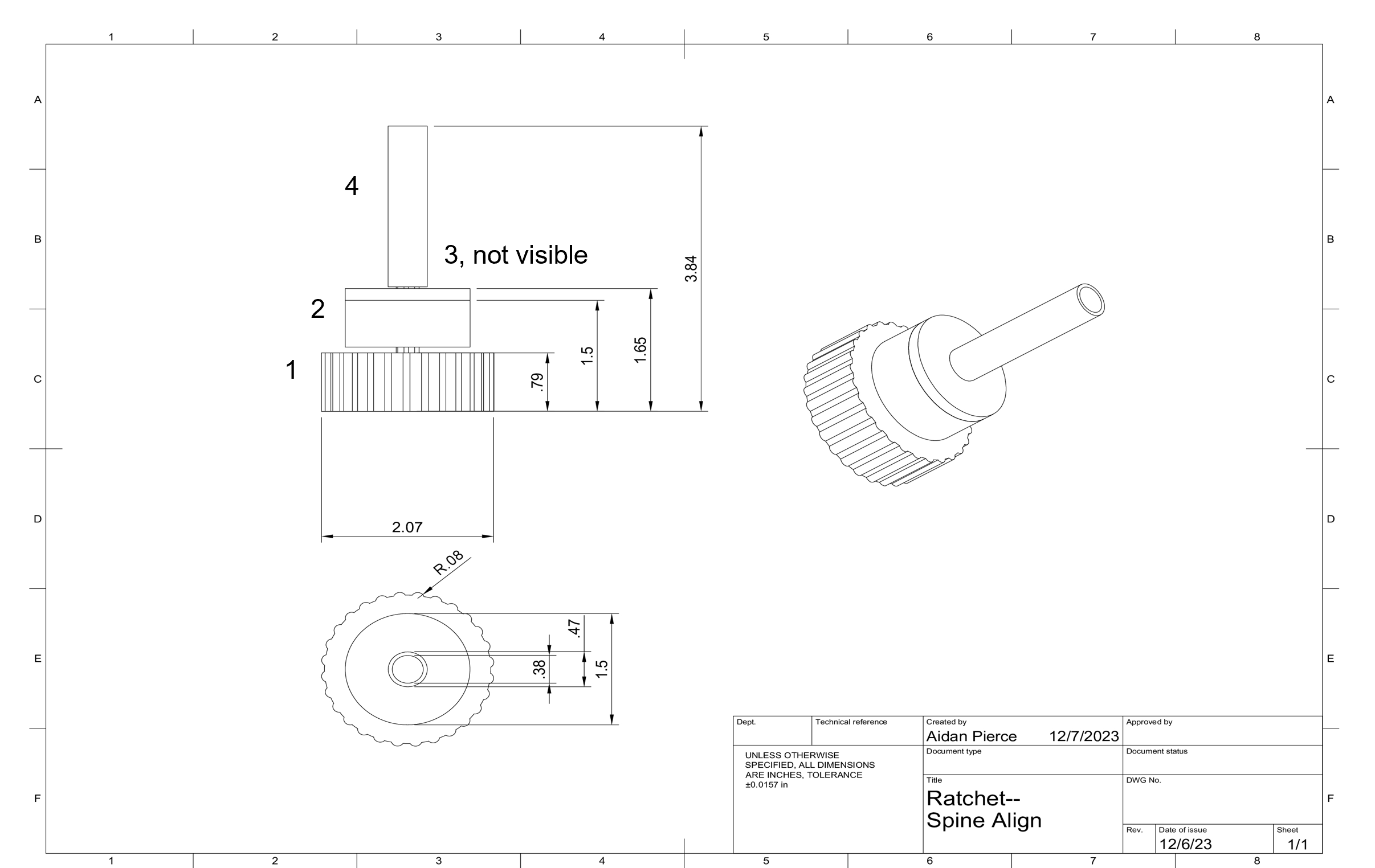

We began with extensive market and consumer research to understand the problem. After analyzing existing products, such as backpack frames and posture correctors, we used a Pugh decision matrix to combine the best features from various concepts into a final design. The chosen solution, called the SpineAlign device, combines a rigid frame to support a backpack with a posture-correcting mechanism. We created low and mid-fidelity prototypes to test our ideas, which were refined with detailed CAD models and engineering drawings. To ensure the design’s integrity, we conducted assembly and tolerance analyses to verify that the components could withstand real-world loads and be mass-produced. Finally, I developed a financial analysis to confirm that the product was both feasible and profitable.

The Outcome

The medium-fidelity prototype demonstrated the potential of the combined design. While a few engineering requirements were not fully met due to the limitations of additive manufacturing, the financial analysis confirmed that with a mass-production method like injection molding, the product would be both feasible and profitable. The analysis projected a production cost of $17.11 per unit, with a retail price of $68.44, which is competitive with existing solutions. The prototype successfully improved posture and provided a rigid structure to support a backpack. The project successfully combined two product categories into a single, functional, and financially viable device, with a projected break-even point in just under three years.

Visual Showcase

Official Report

If you would like to review the full details of this project, you can download the complete reports here: