Optimal Fin Design with Volume Constraint

An investigation into fin geometry’s effect on heat dissipation

Project Overview

Role

As a member of a research team, I contributed to this project by fabricating and testing fins, collecting temperature data, and analyzing the results to determine the optimal fin geometry under a fixed volume constraint.

Project Duration

Spring 2025 Semester

Key Skills

Heat Transfer · Forced Convection · Fin Efficiency · Experimental Testing · Data Analysis · Technical Report Writing

Tools/Software

LabVIEW · Aluminum 6061 · Electric Heater · Blower · Thermocouples · IR Camera

Project Description

The Challenge

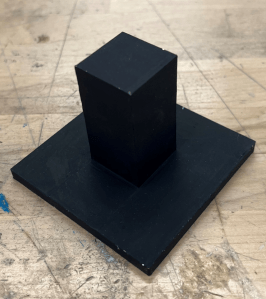

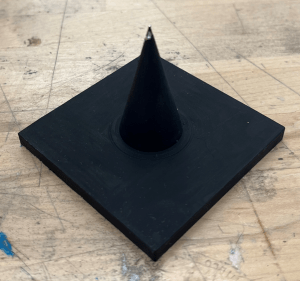

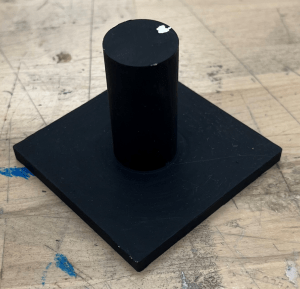

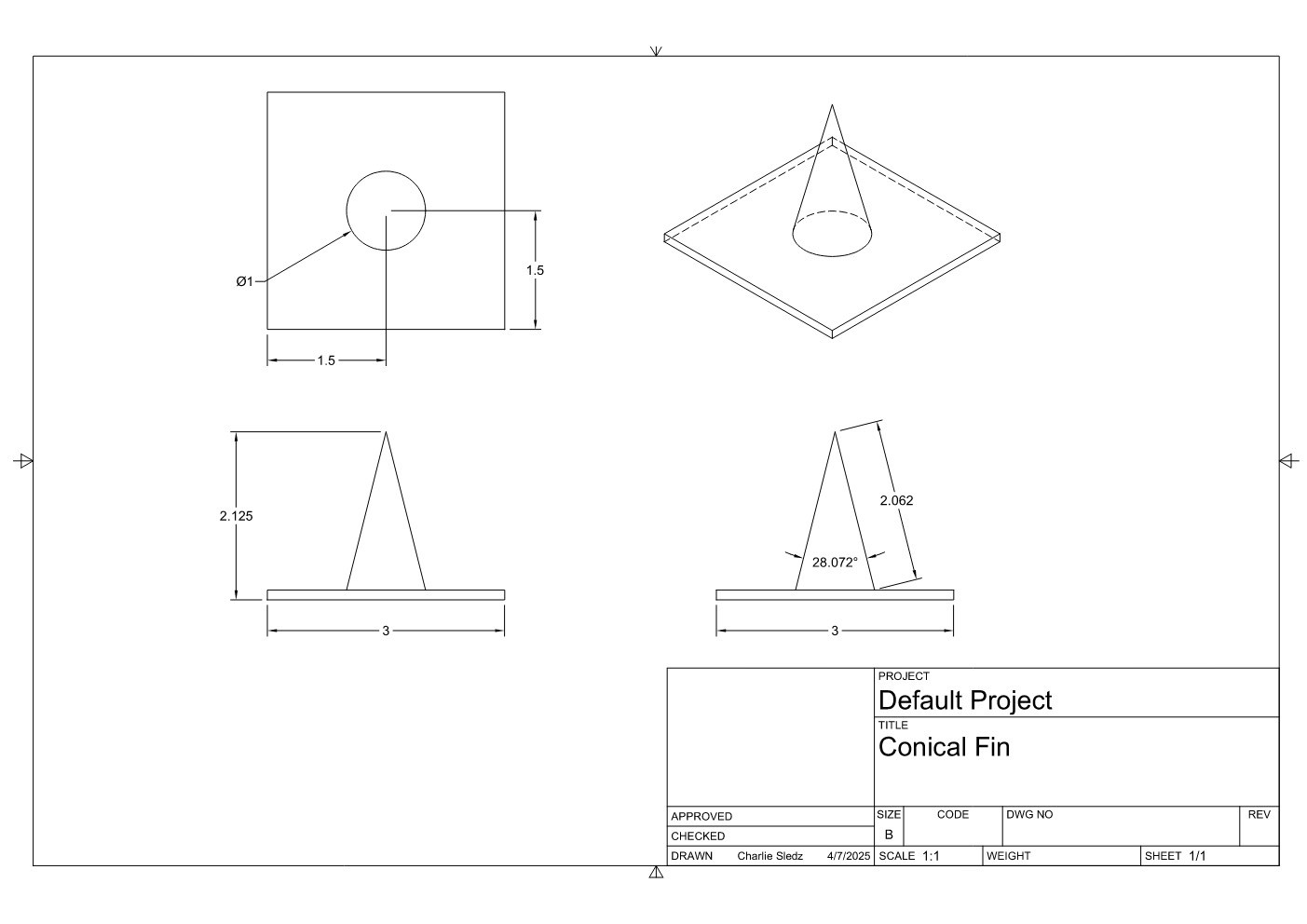

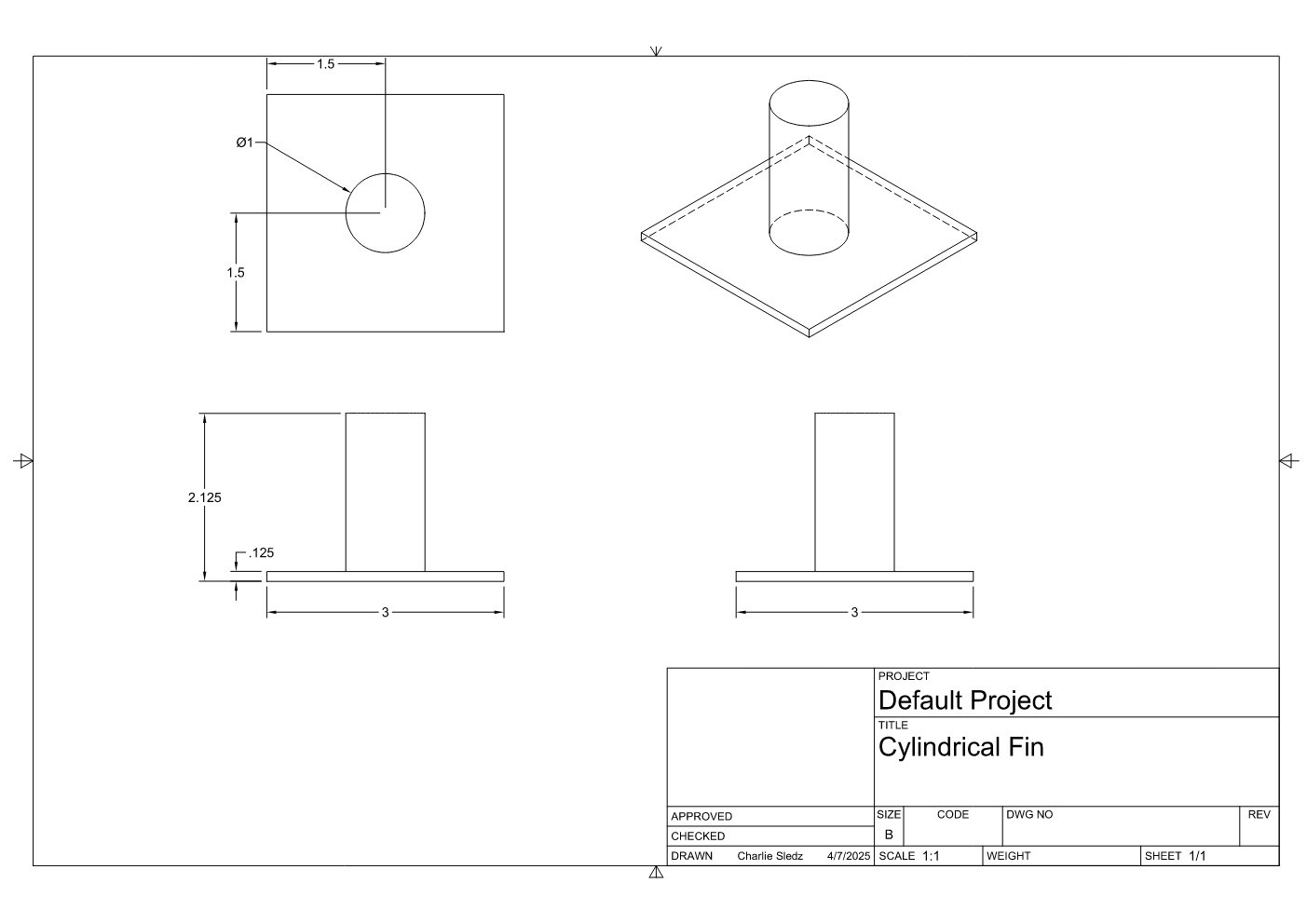

The objective of this project was to determine which of three fin geometries (rectangular, cylindrical, or conical) provides the most efficient heat dissipation within a fixed volume constraint. Fins are critical components in electronics, automotive, and HVAC systems, where maximizing heat transfer in limited space is essential for performance and energy efficiency. We aimed to quantify the heat dissipation efficiency of each design to provide actionable insights for compact thermal designs.

The Approach

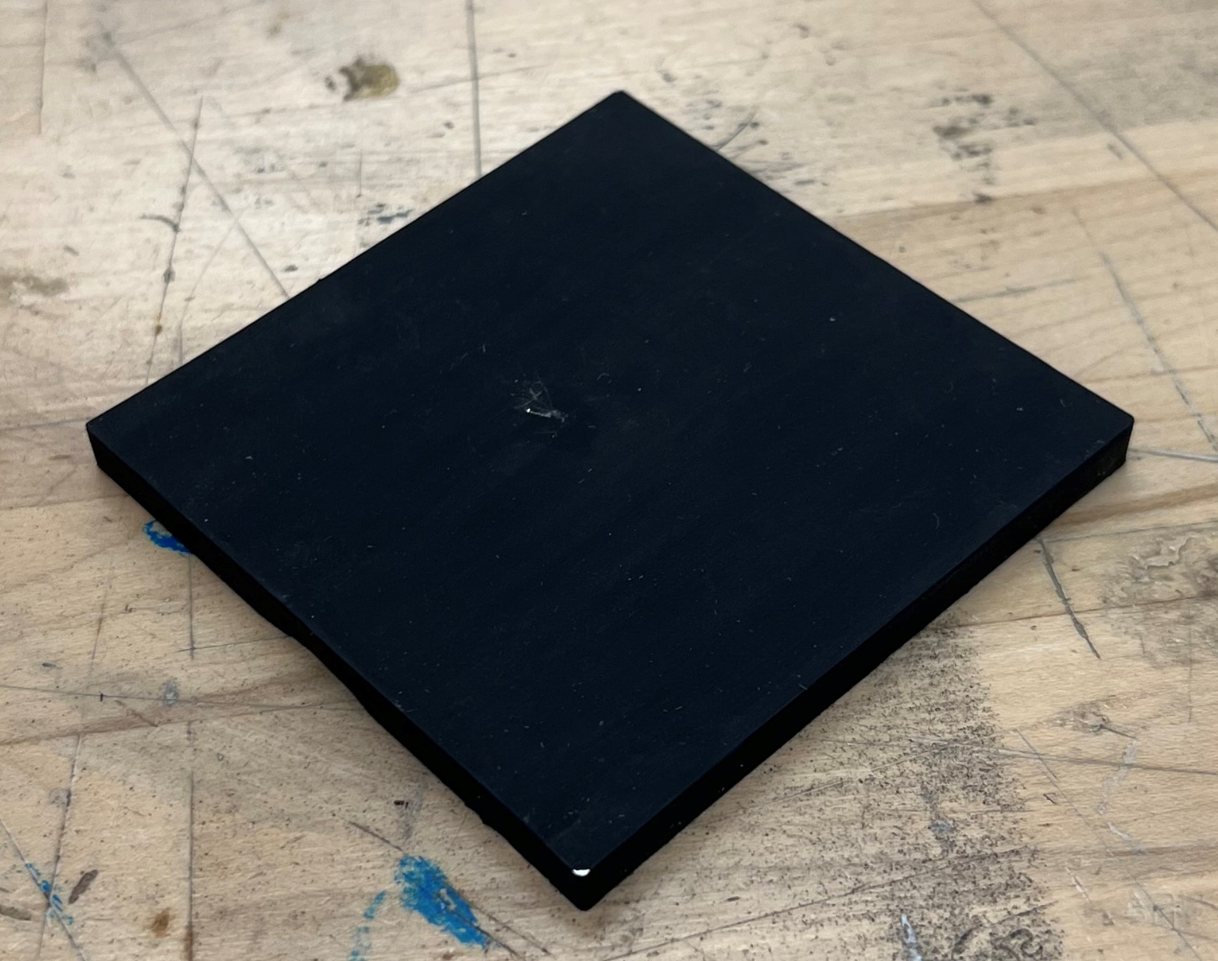

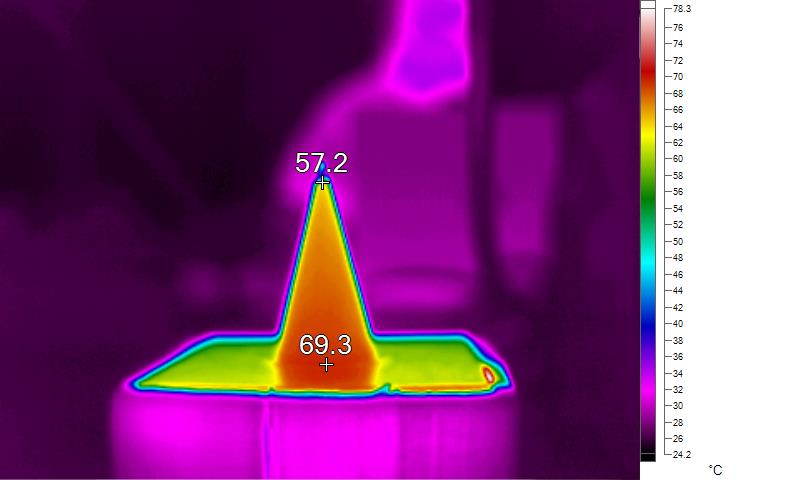

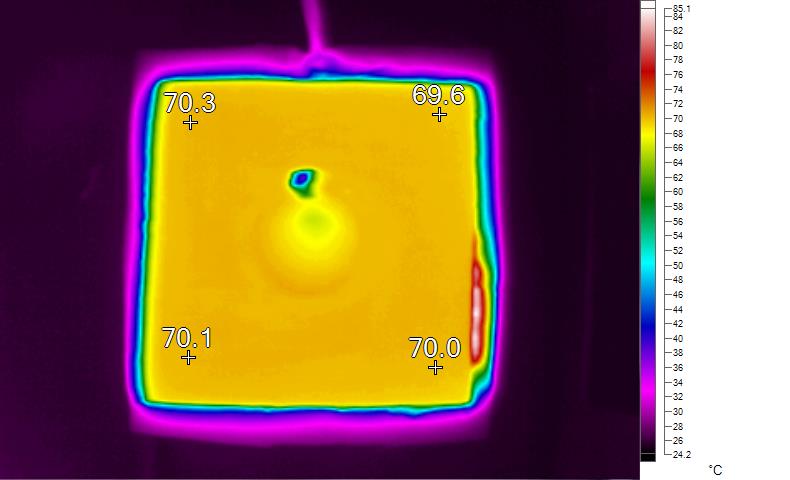

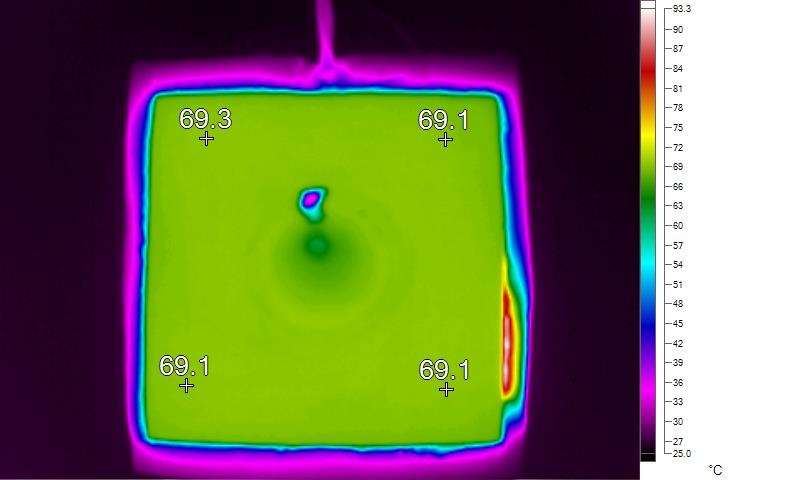

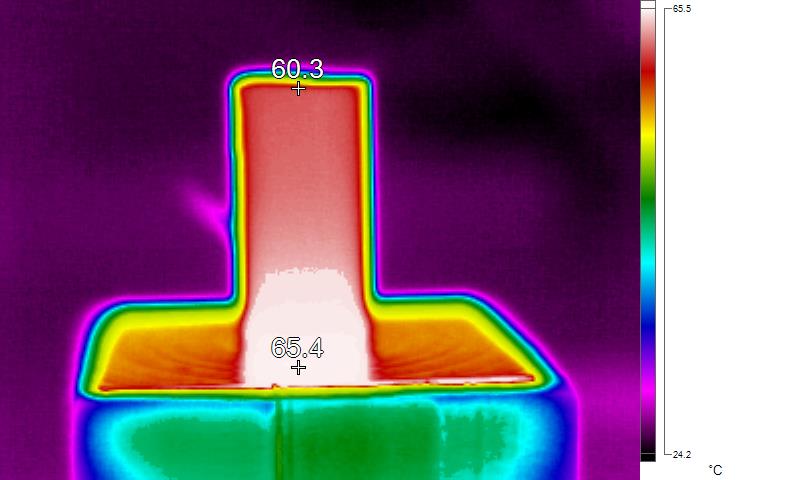

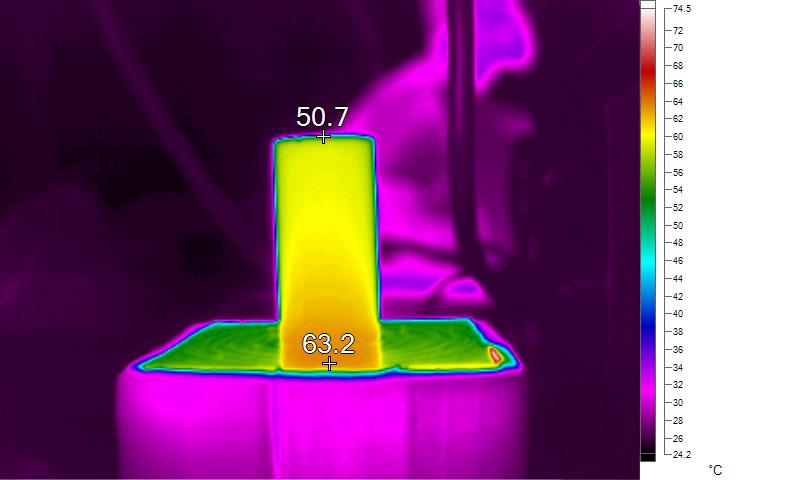

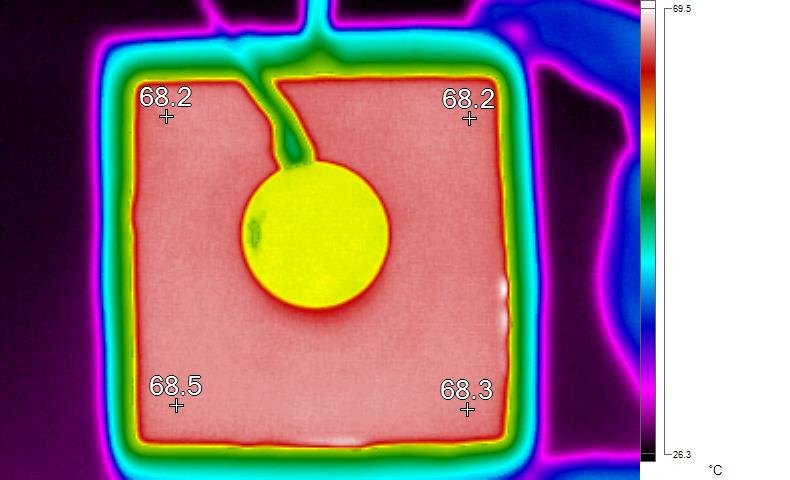

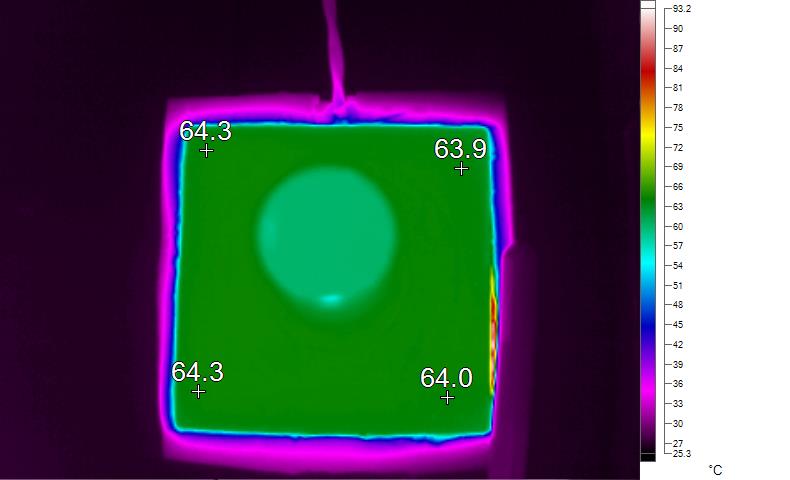

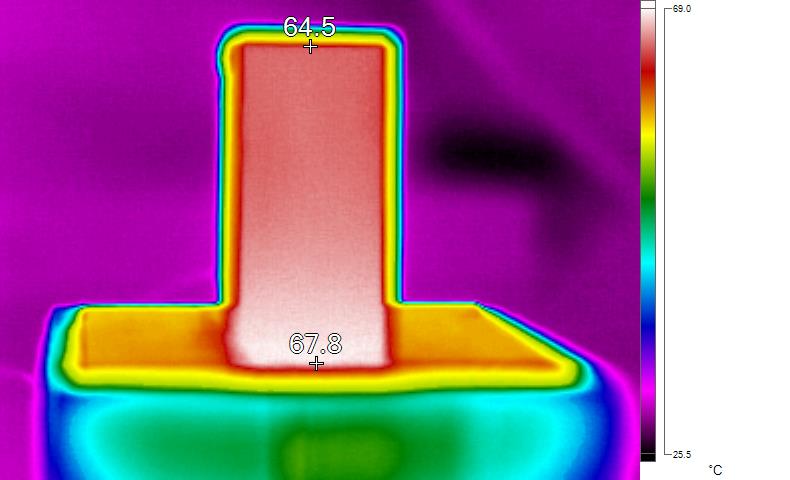

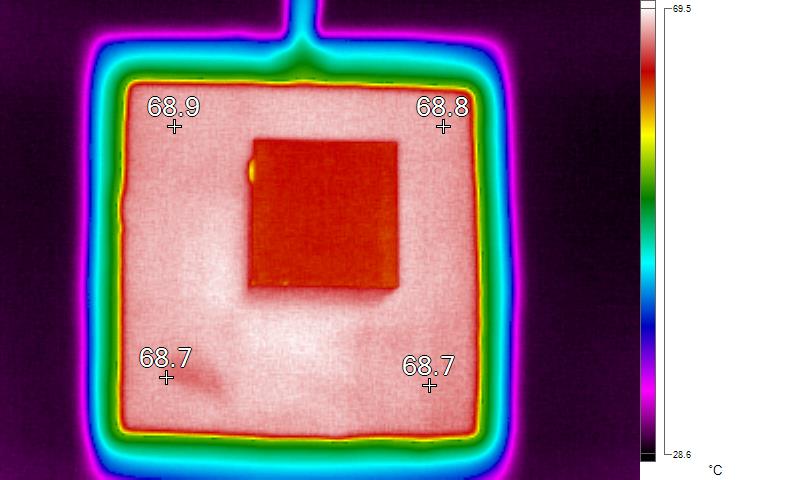

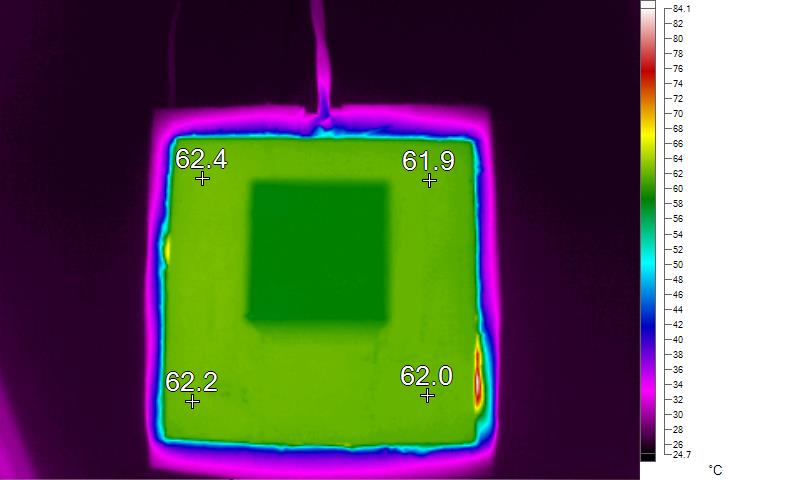

Our team designed and machined three fins (rectangular, cylindrical, and conical) from a single block of Aluminum 6061 to eliminate thermal contact resistance. Each fin, including its base plate, was constrained to a volume of 2 inches in height, 1 inch in width, and 1 inch in depth. We placed each fin on an electric heater within an insulated block and subjected it to a constant 5 m/s airflow from a blower. We used thermocouples and an IR camera to collect temperature data until a steady-state condition was approximated. Using this data, we performed analytical calculations to determine the fin’s heat rate, fin efficiency, and two primary metrics: volumetric efficiency and mass efficiency.

The Outcome

Our experimental results revealed that the rectangular fin had the highest volumetric efficiency, maximizing heat transfer within the specified volume. This was consistent with its ability to fill the entire constrained space, maximizing its surface area. The conical fin, on the other hand, demonstrated the highest mass efficiency, making it the best choice for weight-sensitive applications. This was due to its lighter mass, allowing it to dissipate more heat per gram. The cylindrical fin, while a valid design, did not excel in either metric. These findings provide a clear guide for engineers to select the optimal fin geometry based on specific project requirements, whether it’s for compact, volume-constrained systems or for light-weight, mass-sensitive designs.

Visual Showcase

Official Report

If you would like to review the full details of this project, you can download the complete reports here: